McMaster Industry Liaison Office (MILO)

Information Box Group

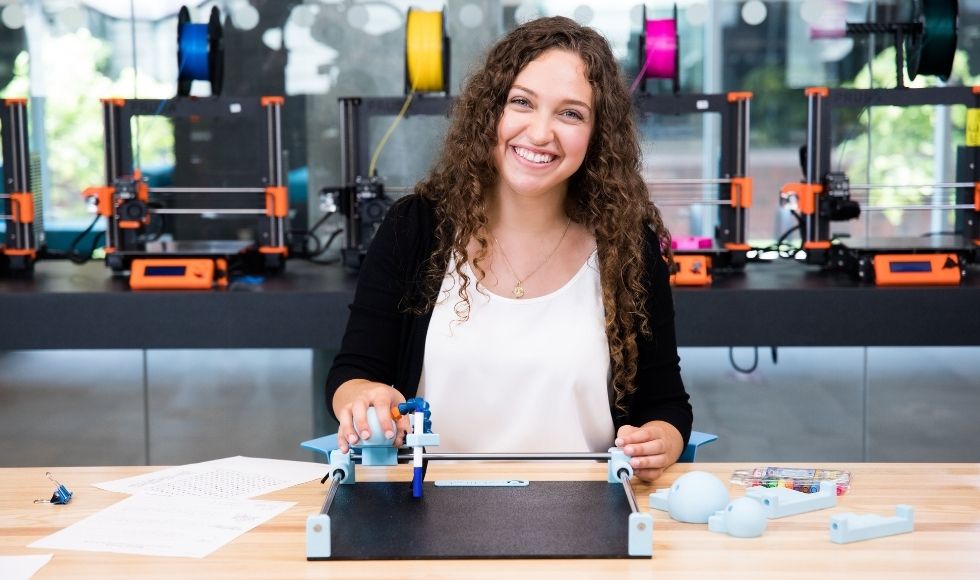

Empowering Researchers for Commercial Success

“I see MILO as the secret weapon behind my commercialization success.”

From facilitating collaborative research with industry partners to securing funding and intellectual property protection, the McMaster Industry Liaison Office (MILO) is here to help McMaster researchers take their discoveries from the lab to the market.

Discover what Mac entrepreneurs say about MILO’s services.

2023 Annual Report

McMaster’s international reputation as a leader in research, innovation and impact is due in no small part to the dedicated faculty, staff and students who conduct ground-breaking research, develop innovative technologies and programs, and mobilize their discoveries to benefit communities on the local, national and global level. MILO’s Annual Report highlights the remarkable work of our research and entrepreneurship community, their successes and some of our key initiatives.

Information Box Group

Three innovative McMaster startups awarded seed funding Read about the MSF Round 3 Investments

Three McMaster startup companies – HARvEST, A.I. VALI Inc. and Esphera SynBio – have each received $256,000 in the third round of McMaster Seed Fund investments.

INTELLECTUAL PROPERTY EDUCATION

Learn the Basics of IP Review our IP education resources

MILO offers many resources for researchers, faculty, and students who want to learn the basics of intellectual property (IP).

Fundamentals of IP at McMaster - Complete Course Register for our IP education course

Take our online course for free! Learn the basics of intellectual property and commercialization at McMaster.